FlareMaXGTG® – Gas to Gypsum

@media only screen and (min-width: 1000px) and (max-width: 5000px){body.kc-css-system .kc-css-3323697{width: 50%;}body.kc-css-system .kc-css-3918519{width: 50%;}}body.kc-css-system .kc-css-2287663{padding-top: 120px;padding-bottom: 120px;}body.kc-css-system .kc-css-939148 ,body.kc-css-system .kc-css-939148 p{font-size: 20px;line-height: 36px;text-transform: capitalize;}body.kc-css-system .kc-css-421570 .kc_button{background-color: #7e878e;}body.kc-css-system .kc-css-2903954 p{margin-top: 40px;}

FlareMaXGTG® – Gas to Gypsum

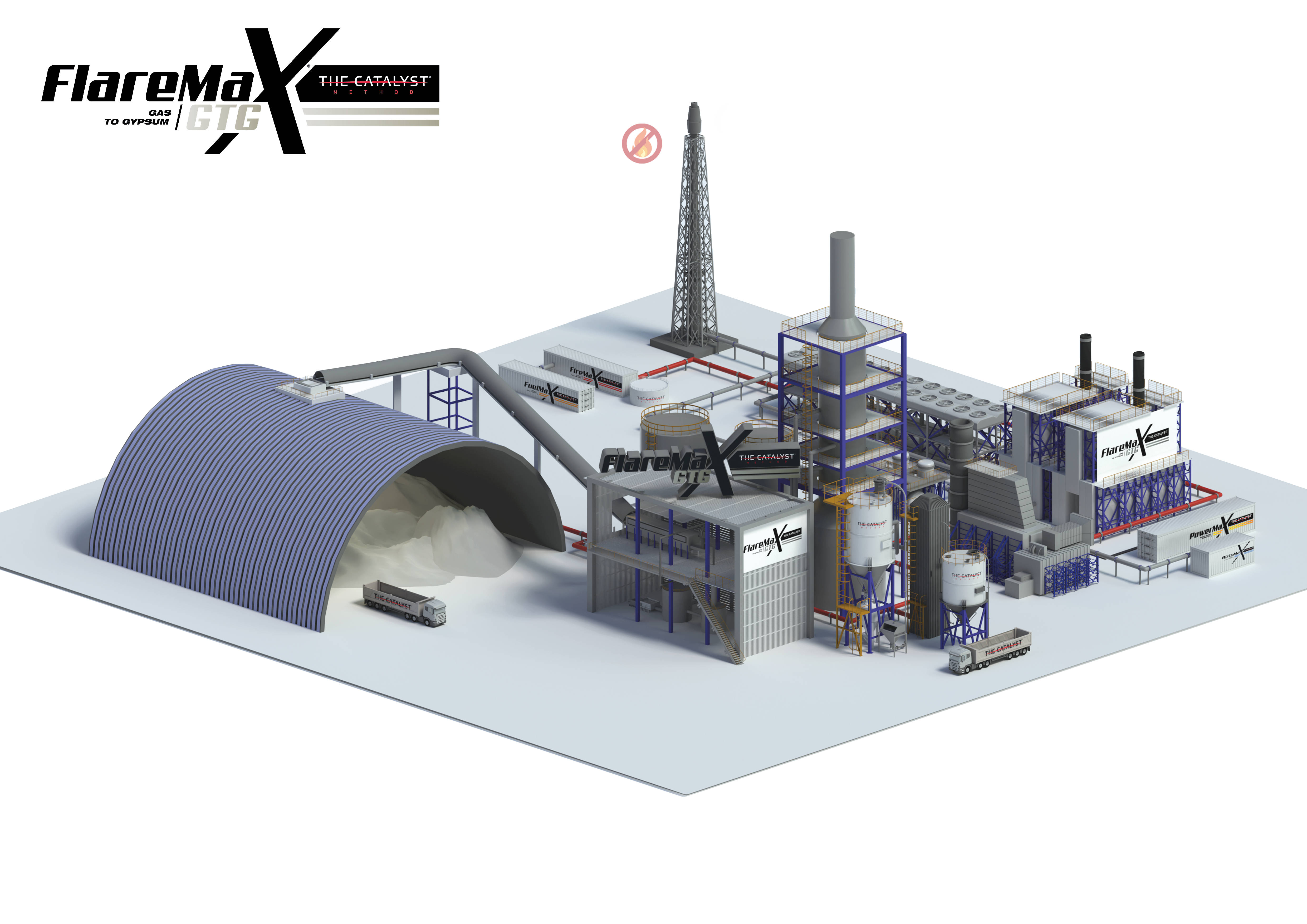

FlareMaXGTG® is modular gas-to-gypsum unit based on the direct conversion of flare gas into Gypsum, Electrical Power and Steam (Heating Media) through the Desulphurization (FPD) Technology.

FlareMaXGTG® is a solution for the disposal of acid gas and the waste H2S product from the existing and future production facilities.

Key Features & Benefits

- Eliminates flaring in an economically feasible manner

- 5.97 Ton of Gypsum is Produced per Ton of H2S in the inlet gas. No Sulphur is produced

- 30% smaller foot-print than traditional unit

- Modular, compact design

- Lower CAPEX and OPEX than a traditional plant

- No special storage requirements, i.e. gypsum can be stored safely on the ground in an open environment

- No catalyst investment and replacement costs and typically 40 to 50 percent lower maintenance costs

- No-grid electricity required

- Excess and residual steam after power generation can be used for meeting plant heating requirements