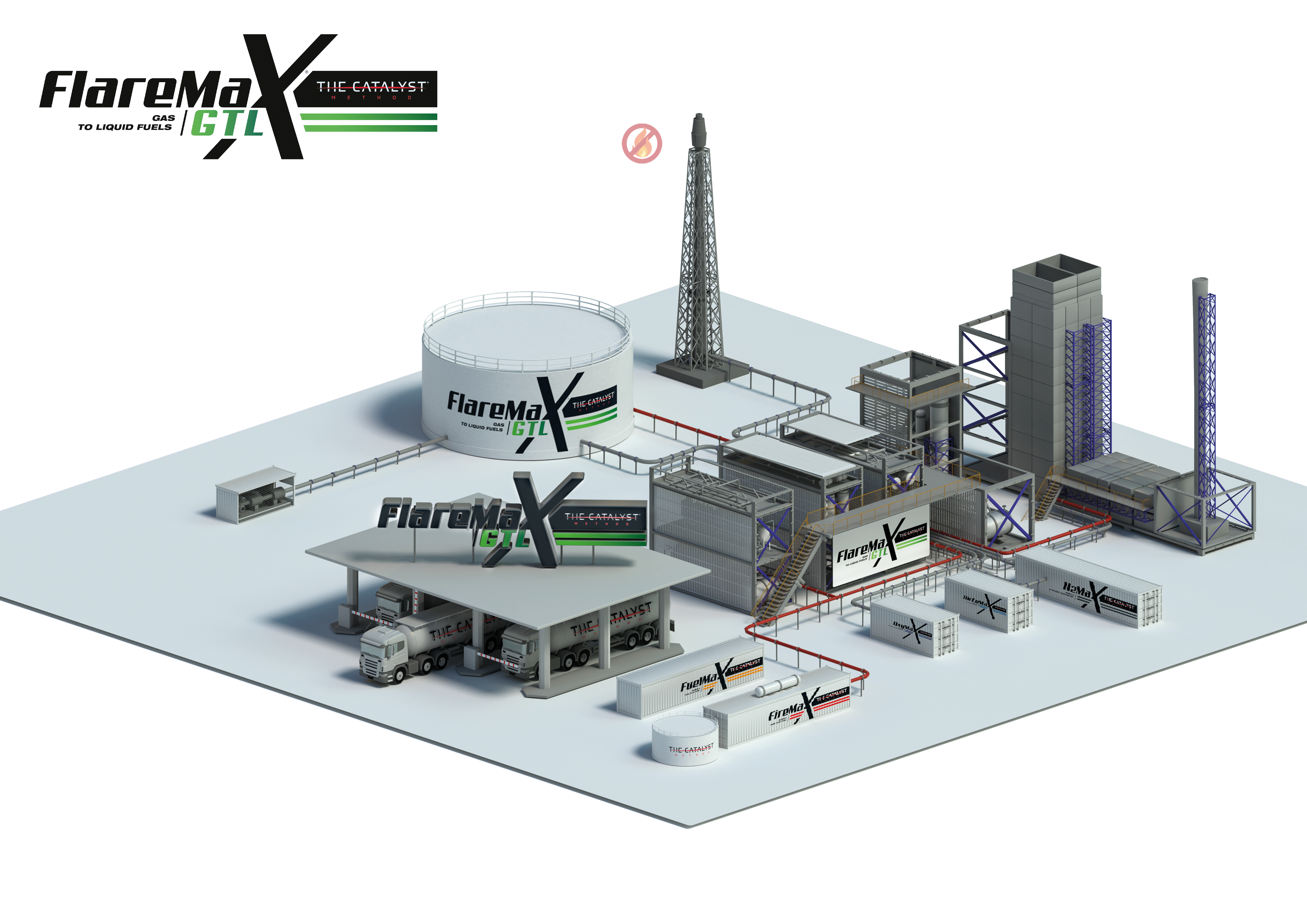

FlareMaXGTL® – Gas to Liquid Fuels

@media only screen and (min-width: 1000px) and (max-width: 5000px){body.kc-css-system .kc-css-3323697{width: 50%;}body.kc-css-system .kc-css-3918519{width: 50%;}}body.kc-css-system .kc-css-2287663{padding-top: 120px;padding-bottom: 120px;}body.kc-css-system .kc-css-939148 ,body.kc-css-system .kc-css-939148 p{font-size: 20px;line-height: 36px;text-transform: capitalize;}body.kc-css-system .kc-css-421570 .kc_button{background-color: #7e878e;}body.kc-css-system .kc-css-2903954 p{margin-top: 40px;}

FlareMaXGTL® – Gas to Liquid Fuels

FlareMaXGTL® is modular gas-to-liquids unit based on the direct conversion of flare gas into synthetic liquid fuel. This liquid is produced directly from the reactor with no hydro-cracking required, and consists of a blend of diesel and gasoline fractions.

A FlareMaXGTP® unit and water recovery block will be added as needed to the basic gas-to-liquid plant configuration to accomplish a self-sustaining plant without the need of an external source of electricity and water.

Key Features & Benefits

- Eliminates flaring in an economically feasible manner

- Converts 1 million standard cubic feet of gas per day info 100 barrels of premium synthetic crude

- High value

- No by-products

- Easily relocated. Modular, compact and movable containerized design

- Lower CAPEX and OPEX

- Synthetic crude is fully compatible with the existing oil infrastructure and is easily upgradable to diesel

- Processes feed gas with varying density

- Handles CO2 rich gas (up to 25% in feed increases the productivity)

- Self-sustained process (no-grid electricity and no fresh water required)

- No requirement for continuous flaring