FlareMaXNGL® – Gas to NGL

FlareMaXNGL® – Gas to NGL

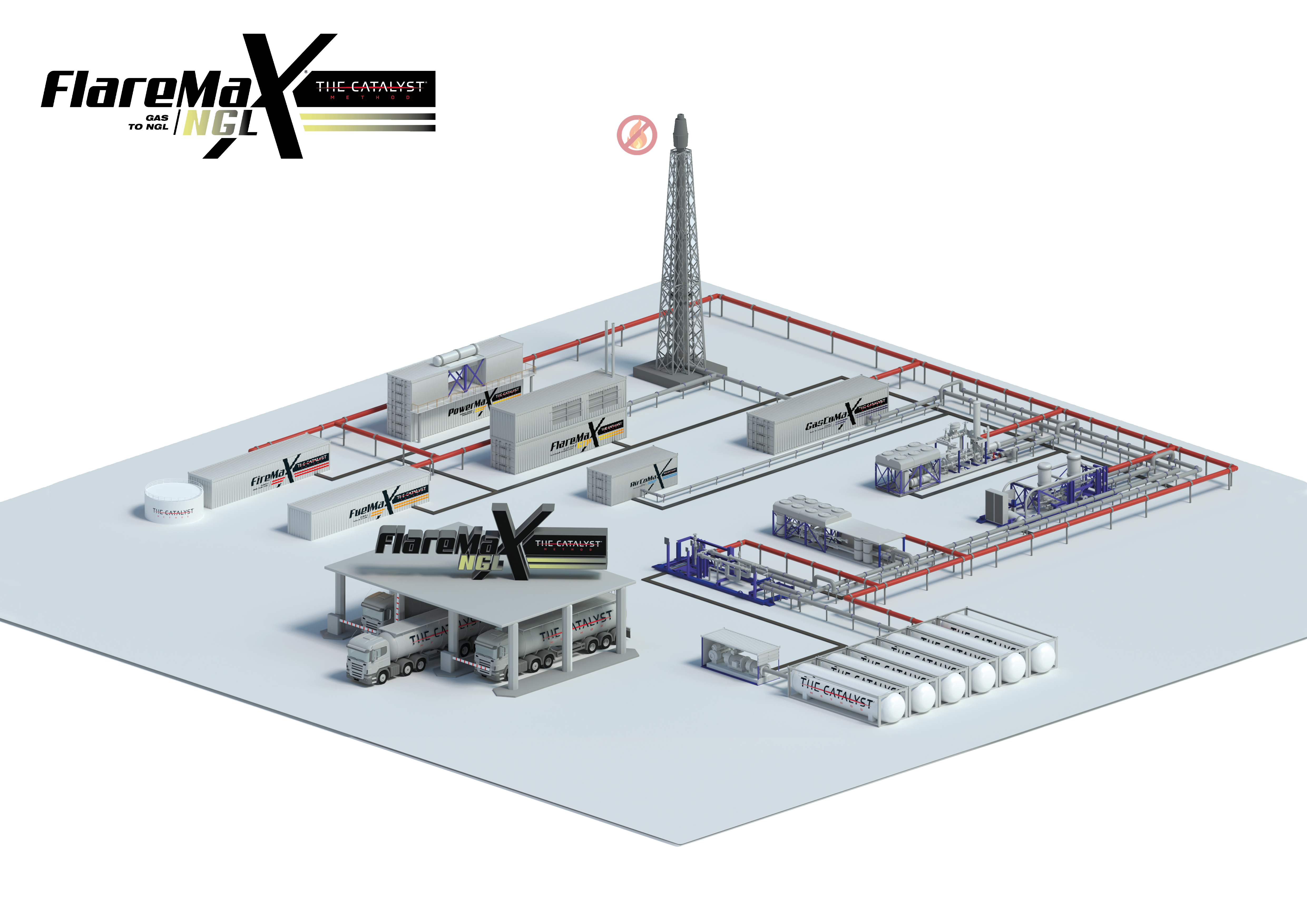

FlareMaxNGL® is a modular gas processing plants recovering Natural Gas Liquids (NGLs) – also referred to as “condensates” or “wet gas“ – from flare, rich, associated and non-associated gas.

Natural gas liquids (NGLs) include ethane, propane, butanes, pentanes and C5+ hydrocarbon molecules.

The mechanical refrigeration-based systems cool gas to different temperatures based on the particular needs of each application and condition the remaining gas to pipeline quality, making it ideal for on-site power generation, conversion to CNG or LNG, feeding into a GTL process, or injection into a lean gas pipeline.

FlareMaxNGL® provides high recovery and high efficiency Natural Gas Liquids (NGL) processes, while optimizing capital and operating costs for customers.

FlareMaxNGL® is delivered completely pre-engineered, modularized, factory tested and plug-and-play in order to deliver turnkey solution for greater efficiencies to our customers.

Key Features & Benefits

- Eliminates flaring in an economically feasible manner

- Converts natural and associated/wasted gas into a value-added product

- Easily relocated. Modular, compact and movable design

- Low CAPEX and OPEX

- Recovered NGLs are fully compatible with the existing oil & gas infrastructure

- Processes feed gas with varying density

- Handles CO2 rich gas