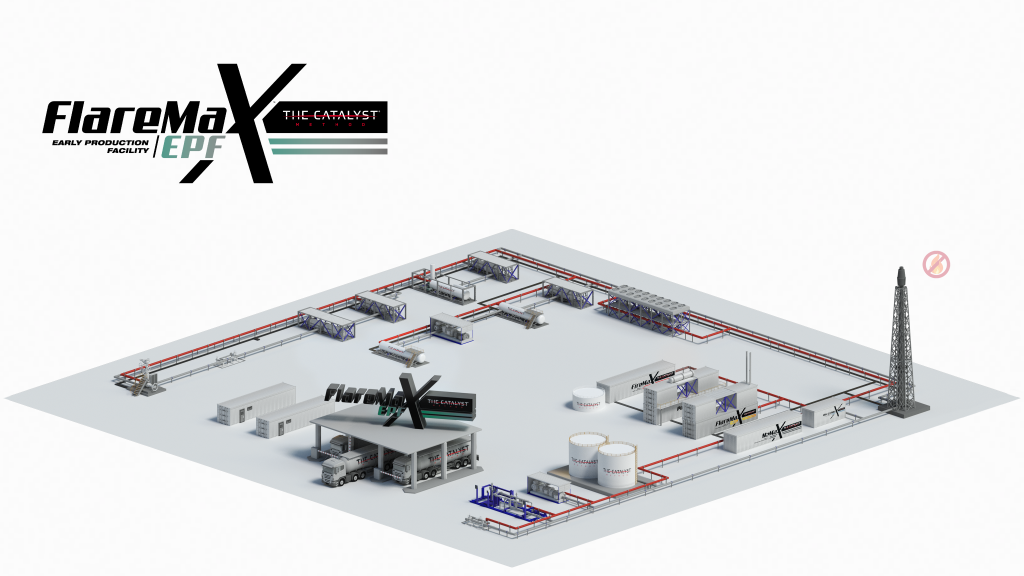

FlareMaXEPF™ – Early Production Facility

FlareMaXEPF™ is a fully modularized Early-Production-Facility meeting the highest international safety and quality standards, enabling high value and earliest possible delivery. This solution can be fully integrated with Gas Utilization and Monetization options that can be delivered within similar time frame, ensuring legislative requirements along with earliest possible production and cost recovery.

The Catalyst Method®, in addition, can offer a truck-able 3 phase production Separator with three phase metering system, which can be used for the earliest possible production (usually within 30 days) and remain in place until the FlareMaXEPF™ and/or additional wells are available.

The basic FlareMaXEPF™ (up to 30kopd) can be delivered within 180 days. It consists of Reception facilities Pig Receiver (s), Inlet Manifold and basic standards equipment, that can be mixed to suit the production profile of and EPF.

The Full FlareMaXEPF™ (up to 30kopd) can be delivered within 270 days. It consists of Reception facilities Pig Receiver (s), Inlet Manifold, crude heat exchangers, 1st Stage Separator, crude heater, 2nd Stage Separator, De-salter (if required), Dehydrator (if required), intermediate pumps, 3rd stage Separator, crude exchanger, air cooling, storage, oil export pumps, truck loading and/or export pig launcher to pipeline.

- Modular, compact design

- Early delivery and production

- Designed for remote operations and difficult locations

- Minimal required construction activities

- Lower CAPEX and OPEX than a traditional plant

- Fully integrable with FlareMaXGTP® (180 days) which enable Power Generation to cover EPF requirements

- Fully integrable with FalreMaXEFW® (180 days) which enable Power Generation, utilizing gas, locally separated at well sites

- Fully integrable with FlareMaXGTL® (270 days) which maintain the objective of zero flaring thanks to conversion of C1 to C4 and CO2 to synthetic crude